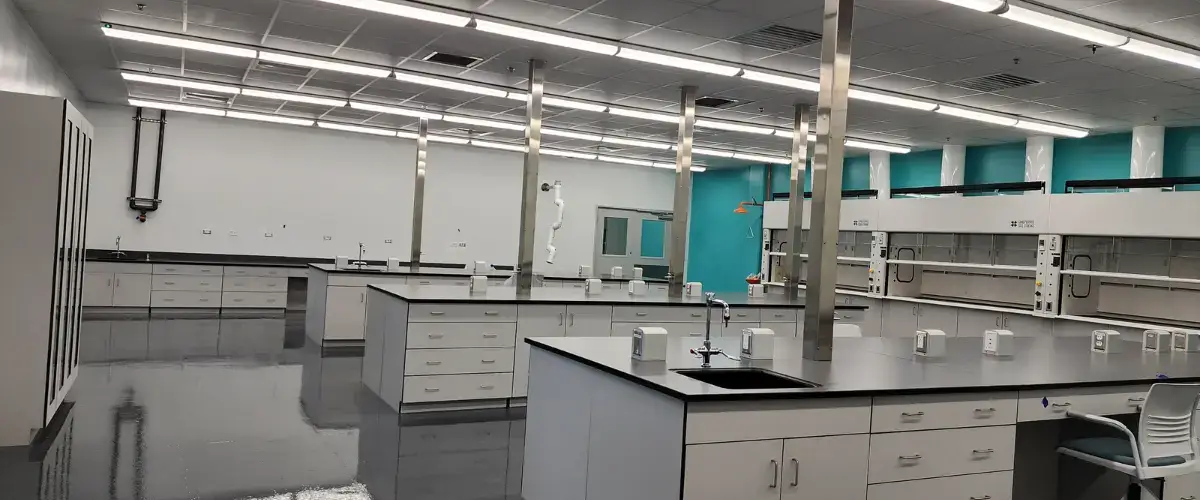

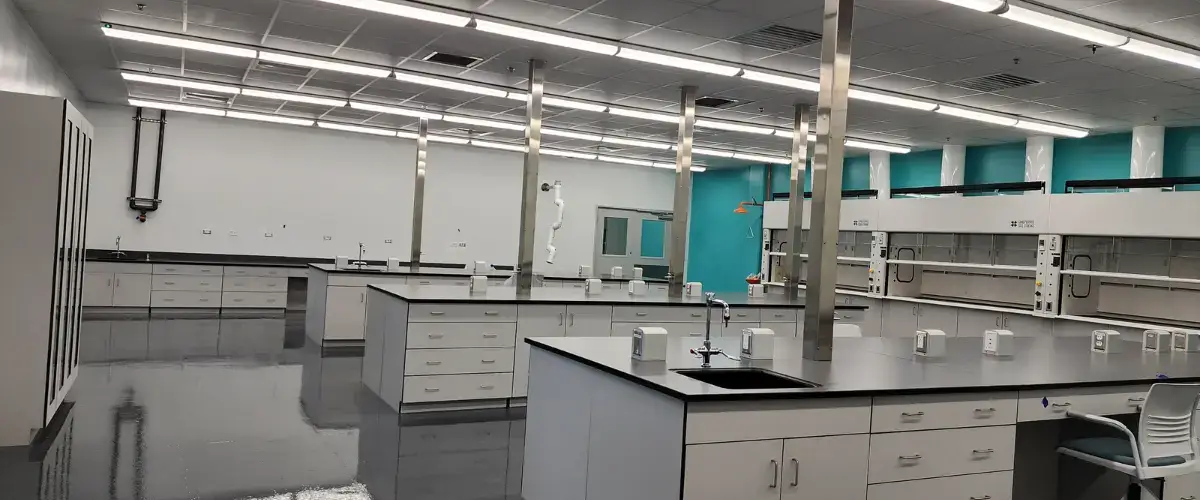

Choosing the right casework is critical in any laboratory design. Whether big or small the right laboratory casework will make or break a lab setting. Material choices affect not only safety, but also, performance, longevity and costs. A rising and versatile option in labs is phenolic resin casework. A nonporous, highly chemical and moisture resistant material used across a plethora of applications from industrial labs to waste water treatment and non-magnetic settings as well.

In this blog, we will touch on what phenolic resin casework (solid phenolic casework) is, understand the pros and cons and offer practical steps to help you on when and not to use this for your lab.

What is Phenolic Resin Casework?

Phenolic resin cabinets come from slabs of phenolic resin which also where countertops and backsplashes are made too. Phenolic resin is made from layering sheets of kraft paper, saturated in a resin, and compressed under high heat and pressure to form a solid panel or countertop.

The process creates a non-porous, chemical resistant material great for scientific and technical spaces.

This kind of casework comes in various configurations from base, including drawer and door units, and sink cabinets to wall mounted storage cabinets and tall cabinets as well. Additionally, as mentioned before, it can be work surfaces in laboratories where there is frequent exposure of moisture, chemicals and abrasions as well.

Benefits of Phenolic Resin Cabinets

- Excellent Chemical Resistance – Phenolic resin is designed to withstand aggressive cleaning agents, solvents, and mild acids, making it ideal for chemical labs and wet areas. According to Durcon, a leading manufacturer of lab surfaces, phenolic resin resists damage from most common lab chemicals.

- Water and Mold Resistance – Unlike wood-based laminates, phenolic resin does not absorb moisture. This makes it suitable for high-humidity environments or areas exposed to frequent washing. In addition, phenolic resin casework is termite resistant as well. Making it a great choice if a lab is located where termites come into contact more than desired.

- High Durability – Phenolic casework is extremely durable and resists physical wear, scratches, and abrasions—important in high-traffic or student-focused labs.

- Cost-Effective – While not the cheapest option available, phenolic resin strikes a balance between performance and cost. It offers many of the benefits of higher-end materials at a more accessible price point.

Drawbacks of Phenolic Cabinets

- Heavy Design – Compared to other casework materials like stainless steel, powder coated metal, polypropylene and laminate, phenolic resin cabinets are unfortunately heavy to install in the field. Thus having experienced installers and/or aids in a seamless set for the lab. At OnePointe Solutions, we offer installation services for phenolic resin casework along with our other various products making us a one stop shop for your lab furniture needs.

- Costly – Though a cost effective option, phenolic resin casework is still an expensive choice upfront due to is material composition, regulations and compliance standards, performancecapabilities and manufacturing process. However, it surpases other lab materials due to its durability, chemical resistance and lifespan.

Ideal Applications

Phenolic resin cabinets are well-suited for:

- Pharmaceutical and R&D Labs – Effective in cleanable, semi-sterile environments with moderate chemical usage.

- Food and Beverage Labs – Moisture resistance and ease of cleaning make it suitable for HACCP-compliant labs.

- Clinical and Diagnostic Labs – Resistant to biological stains, mild acids, and sanitizers.

- Industrial QA/QC Labs – Stands up well to heavy equipment and tools.

Where Not to Use

While phenolic resin cabinets and casework have various application uses, it’s not always the right choice. Below are some scenarios of when to avoid it:

- High Heat Applications: Phenolic resin does have heat resistance, but up to 350 degrees and can only be exposed for short periods. If exposed to extremely high temperatures for long periods it can degration.

- Cleanrooms or Sterile Environments: Although resistant to moisture and bacteria, phenolic resin casework is not as hygienic as stainless steel which is primarily used in in these spaces due to the fully welded and sealed elements of it. Phenolic resin casework does not have this.

Pros and Cons of Phenolic Resin Cabinets

Pros

- Strong Chemical Resistance

- Moisture- and Mold-Resistant

- Long-Lasting with Minimal Maintenance

- Termite Repellant

- Various Acceptable Applications

Cons

- Unsuitable for Cleanrooms or Flame-Exposed Environments

- Can Scratch Under Heavy Mechanical Abuse

- Limited Color/Finish Customization

- Can be Difficult to Repair Once Damaged

- Heavy to Install

Alternatives to Consider

Materials

- Stainless Steel

- Epoxy Resin

- High-Pressure Laminate (HPL)

Best For

- High heat, flame resistance, sterile environments

- Extreme chemical exposure, heat, and impact (countertops)

- Budget-conscious labs with minimal exposure risks

Need Phenolic Resin Cabinets for Your Lab?

Phenolic resin casework offers an outstanding mix of chemical resistance, durability, and cost-efficiency—making it a go-to solution for many modern laboratories. However, it’s not a one-size-fits-all answer.

At OnePointe Solutions, we help lab planners and architects specify the right material for different laboratory applications. Whether you’re designing a high school science lab or a pharmaceutical R&D facility, our team can help you determine if phenolic resin is the best.

Contact us today to get started – (866) 215-5847.