Mechanical testing laboratories are paramount to comprehending how materials and components perform under to understanding how materials and components perform under various stress conditions. From aerospace and automotive to heavy manufacturing and other industrial applications, these laboratories provide critical data that determine factors like product safety, reliability, and compliance. Designing mechanical testing lab requires more than just floor space—it requires careful planning around the building/housing structure, equipment and machinery loads, workflow, and environmental controls to name a few.

Whether you’re converting an existing space or starting from scratch, this guide outlines everything you need to know about designing a mechanical testing lab that delivers precise, repeatable results.

What is a Mechanical Testing Lab?

To start, let’s define what a mechanical testing lab is: These are specialized facilities where materials for tested for mechanical properties like tensile strength, impact resistance, fatigue and hardness. The results, are then used for:

- Product validation during research and development (R&D)

- Meeting regulatory or industry standards (ASTM, ISO, EN)

- Quality control in production environments

- Failure analysis after product malfunction

Mechanical testing laboratories aid various types of manufacturers to foresee product behavior under real-world conditions, ensuring reliability, safety and cost-efficiency across product lifecycle. Now that we understand the what and the importance

Key Design Considerations

Designing a successful mechanical testing lab begins with an understanding of how materials behave under force—and how that force impacts your lab layout, infrastructure, and equipment needs.

Structural Reinforcement and Load Capacity

Mechanical testing machines such as universal testing machines (UTMs), impact testers, and fatigue testing rigs are large and heavy. These machines can exert intense downward force during operation. To accommodate this:

- Reinforce concrete slabs under heavy equipment

- Isolate test machines with vibration-dampening platforms or pads

- Ensure subfloor systems are rated for point loads exceeding several thousand pounds

- This prevents vibration transfer, inaccurate readings, or even structural failure over time.

Environmental Control and Test Integrity

Temperature, humidity, and air movement can all influence test results. Sensitive materials may expand or contract with temperature shifts, which can skew data.

Maintain a consistent temperature (typically around 20–23°C or 68–73°F) with minimal fluctuations.

Ensure adequate ventilation without causing drafts near testing equipment.

If performing elevated temperature tests, segregate thermal test areas with appropriate exhaust systems.

Workflow Layout: From Sample to Report

Efficient lab design should follow a logical workflow. Begin by mapping the journey of a test sample from entry to final analysis. Below are some recommended zones and areas you may want to include in your lab.

Recommended Zones:

- Receiving & Sample Prep: Materials logged, cut, or conditioned

- Testing Spaces: Houses tensile testers, hardness testers, etc.; often the noisiest and most space-intensive zone

- Data Analysis Area: A quieter area or room for engineers/technicians to review testing results

- Storage: For tooling, small equipment, fixtures, calibration equipment, and archived samples

Clearly separating these zones helps reduce contamination, improve safety and prevents unnecessary bottlenecks.

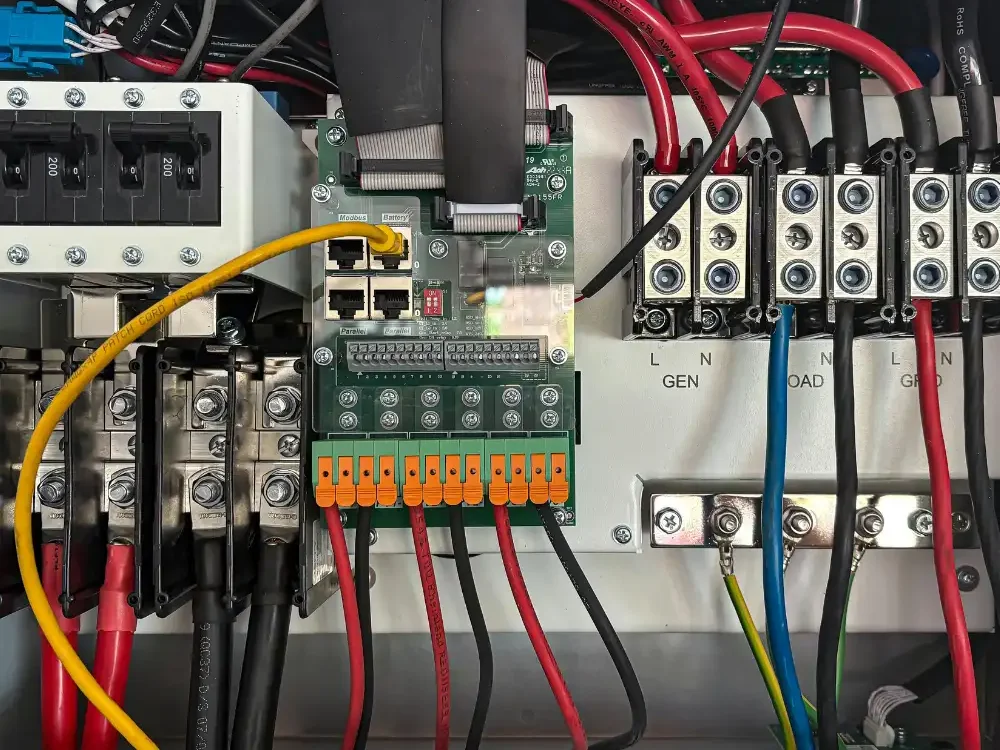

Power, Data, and Utility Infrastructure

Modern mechanical laboratories need significant power and data connectivity. To avoid clutter and improve maintenance, do the following:

- Install isolated power circuits with voltage protection for precision instruments

- Use trenching or floor-mounted power boxes near heavy machines

- Ensure adequate data outlets and Wi-Fi coverage for lab software and cloud-integrated testing platforms

Dedicated clean power reduces electrical noise, which can interfere with digital sensors and load cells.

Safety First

With any kind of laboratory, safety needs to be at the forefront. With that being said, high-force mechanical testing introduces potential hazards including flying debris (in impact tests), pinching points, or even part failure under load. To help mitigate risks:

- Install transparent protective screens around machines

- Use emergency stop buttons near each workstation

- Clearly mark safety zones and walkways

- Provide PPE such as gloves, face shields, and ear protection

Having compliance with OSHA, NFPA, and local building codes is non-negotiable—especially in labs operating under accreditation or regulatory oversight. Better to be safe than sorry and here safety is required.

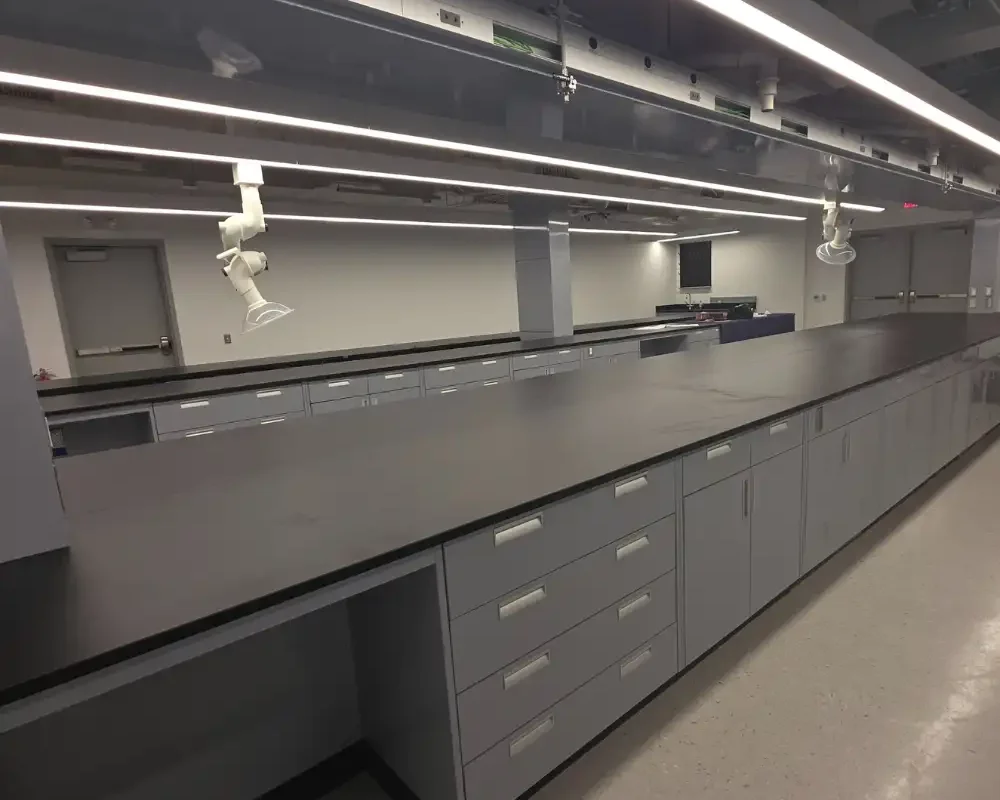

Furniture and Equipment Recommendations

Selecting the right lab furniture impacts not only durability, flexibility, adaptability, and ergonomics. Some recommended furnishings include:

- Heavy-duty laboratory tables and benches: steel frames with leveling feet and/or vibration dampening options

- Laboratory countertops: epoxy resin, phenolic resin, solicor-cr or stainless steel

- Mobile carts or tables: to easily maneuver specimens between zones

- Lab storage cabinets: organization of tools and documentation.

Why a Thoughtful Lab Design Matters

A well optimized mechanical testing lab isn’t just functional, it’s a strategic assets. Proper design ensures accuracy and consistency in test results, increases personnel safety, and minimizes costly downtime. In industries where every micron and newton counts. precision in lab design supports better engineering decisions and faster product development cycles. Mechanical testing laboratories are complex environments where poor design directly affect results. Prioritizing infrastructure, layout, and workflow ensures your lab can meet increasing demands of modern materials testing and remain compliant with industry standards.